Product Information

Chemical Name:γ-Aminopropyltriethoxysilane

Product Code:LT-550

Molecular Formula:C9H23NO3Si

Molecular Weight:221.4

CAS NO.:919-30-2

Properties and Reactivity

LT-550 is a bifunctional silane with reactive amino groups and hydrolysable inorganic ethoxysilyl groups. With its reactive dual nature, it is capable of organically bonding inorganic materials (e.g., glass, metals, fillers) to organic polymers (e.g., thermoplastics, thermosets, or elastomers). It is used as a tackifier, surface modifier for organic/inorganic interfaces (corrosion protection, primers) or as a silicone polymer or crosslinker (moisture crosslinking polymers).

It is a colourless, transparent, low-viscosity liquid with a distinct ammonia odour, soluble in alcohols, aliphatic or aromatic hydrocarbons. In addition, it is completely soluble and reacts immediately with water.

LT-550 is hydrolysed in the presence of water to form reactive silanol groups, which can form bonds with a wide range of inorganic substrate surfaces.

The hydrolysis of LT-550 can be catalysed by organic acids such as acetic acid.

Suitable inorganic materials include: glass, glass fibre, glass wool, mineral wool, silica, sand, mica, aluminium hydroxide, quartz, calc-silica, kaolin, talc, other silicate fillers, metal oxides and metals.

Resins that can be used in LT-550 include, epoxy, phenolic, furan, melamine, polyurethane, PA, PBT, PC, EVA, modified PP, polyvinyl butyral, PAVC, PVC, PS, elastomeric rubbers, acrylics, and silicone resins.

LT-550 reacts in ketone or ester solvents. The silane itself or the silanised substrate reacts with carbon dioxide to form the corresponding carbonate or carbamate. Material modification with suitable monomers or polymers (e.g. isocyanates) is carried out by addition reactions.

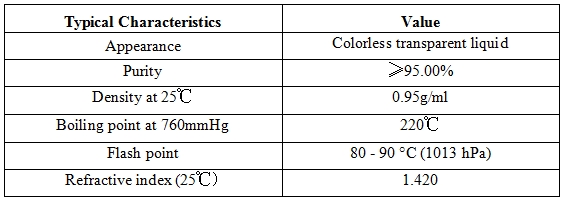

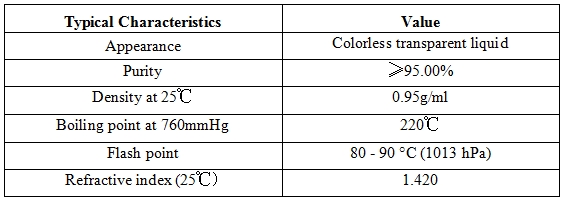

Technical Data

Note: the above data is for reference only, cannot be as a technical specification.

Application

Coatings, adhesives and sealants

LT-550 is a good adhesion promoter in acrylic coatings, adhesives and sealants. It is used with polysulfides, urethanes, room temperature vulcanised silicone rubber, epoxy resins, nitrile rubbers, phenolic resins in adhesives and sealants, where it increases the dispersion of the filler and maximises the adhesion of the filler to glass, aluminium and steel.

Glass-reinforced resin systems

In glass fibre reinforced thermosetting plastics, LT-550 can greatly improve and enhance the physical and mechanical properties such as dry and wet flexural strength, compressive strength, shear strength, etc. of plastics and wet electrical properties.

Glass fiber and mineral wool insulation

used as an additive in phenolic resin binders, LT-550 gives excellent moisture resistance and elastic recovery..

Mineral-filled resin systems

LT-550 helps to maximise the physical and electrical properties of mineral-filled phenolic resins, epoxy resins, polyamides, polyterephthalic acid and many other thermoset and thermoplastic composites. Wetting and dispersion of the filler in the polymer matrix is also typically improved.

Foundry applications

In shell molding, it can help strengthen the bond between the phenolic binder and foundry sand.

Grinding wheels

In the manufacture of grinding wheels, LT-550 helps to improve the phenolic resin bonding and water resistance of abrasion-resistant self-hardening sand.

鄂公网安备 42900402000406号

鄂公网安备 42900402000406号 Home

Home Tel

Tel Product

Product